At KMW, we specialize in melting and casting Brass & Copper through the Horizontal Continuous Caster. Brass is a metal fabricated mainly of copper and zinc. Copper is an essential element in many products due to its superior conductivity and corrosion resistance properties. We are proud to provide our customers with the highest quality Copper & Brass products possible.

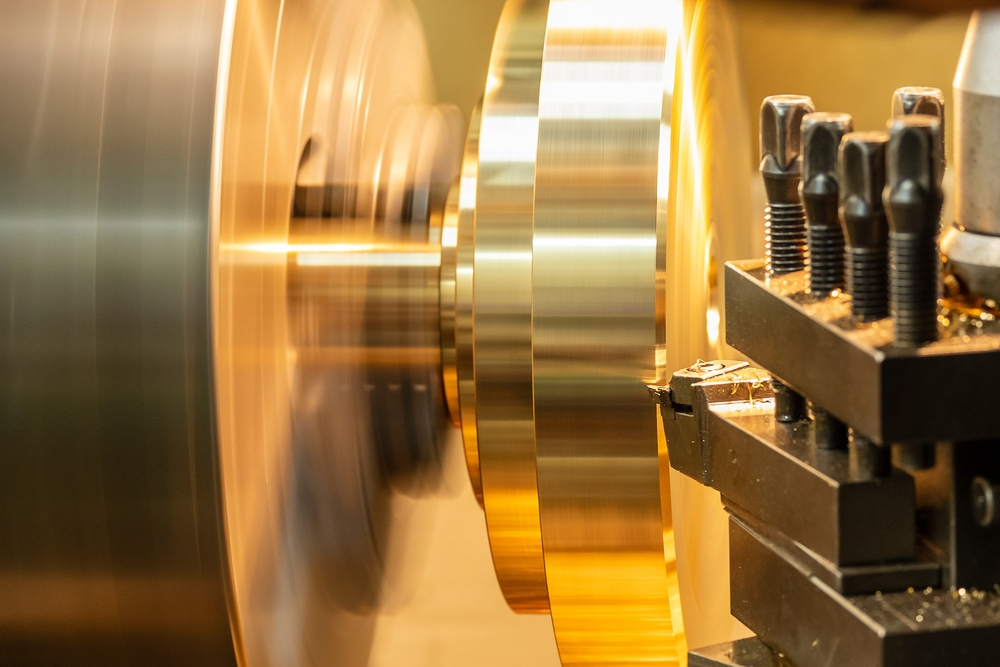

A fair quantity of suitable copper alloy scrap is weighed and repositioned into an electric induction furnace where it is liquefied at approximately 980°C to 1180°C Temperature, pivoting on the composition. After acclimating to the quantity of zinc in the scrap alloy, a proper portion of zinc is added once after the entire copper melts. An extra amount of zinc is added to balance zinc that vaporizes during the melting procedure. Molten metal is repositioned in the holding furnace using launders. The material is grazed in the water-cooled die and once after solidification, it is extracted out in the strip form & eventually in Coils form.

We have a horizontal continuous Strip Casting Line Imported Wertli Switzerland Make for 4 MT Coils weight for the Strip Casting of Copper and its alloys. Contemporary casting technology allows us to produce state-of-the-art continuous un-welded coils of specific chemical composition. Computer-controlled explicit reading spectrometer helps in scanning the chemistry of the molted metal.